Repair Manual Buick Lesabre Transmission Model 4t65e

The problem is this; the car shifts okay, meaning it shifts when it's supposed to and fairly smooth, but there is a definite 'clunk' after it's shifted into the next higher gear. This is my wife's car so I don't drive it as much as she does so I don't know when it actually started, but from my experience on a recent trip to Florida, it only does it when hot. And the problem will go away (if only briefly) if you shut the car off and let it cool down for 30 minutes or so. We just returned home so I haven't had a chance to check in to repairing it, either myself or paying to have it done. Hopefully it's a job I can do myself.

Mon Apr 28, 2008 Bought a 102k mile 1998 4T65E-HD out of a Regal GS from local Craigslist. Seller is a 50-ish high school auto shop teacher. Story is: Bought the car at auction (rear-ended) for the front clip for his son's (front-wrecked) car. Donated the engine to the shop class for tear-down, and let the kids take home whatever parts they wanted (yes, the M90 was gone ). Says he drove it home with temporary tail lights stuck to the trunk lid, and the only significant trans issue was that the TC lockup would drop in and out; suspects a valve body issue. He'd been trying to sell it for 5 months now, gradually dropping the asking price from $250 to the $100 I got it for.

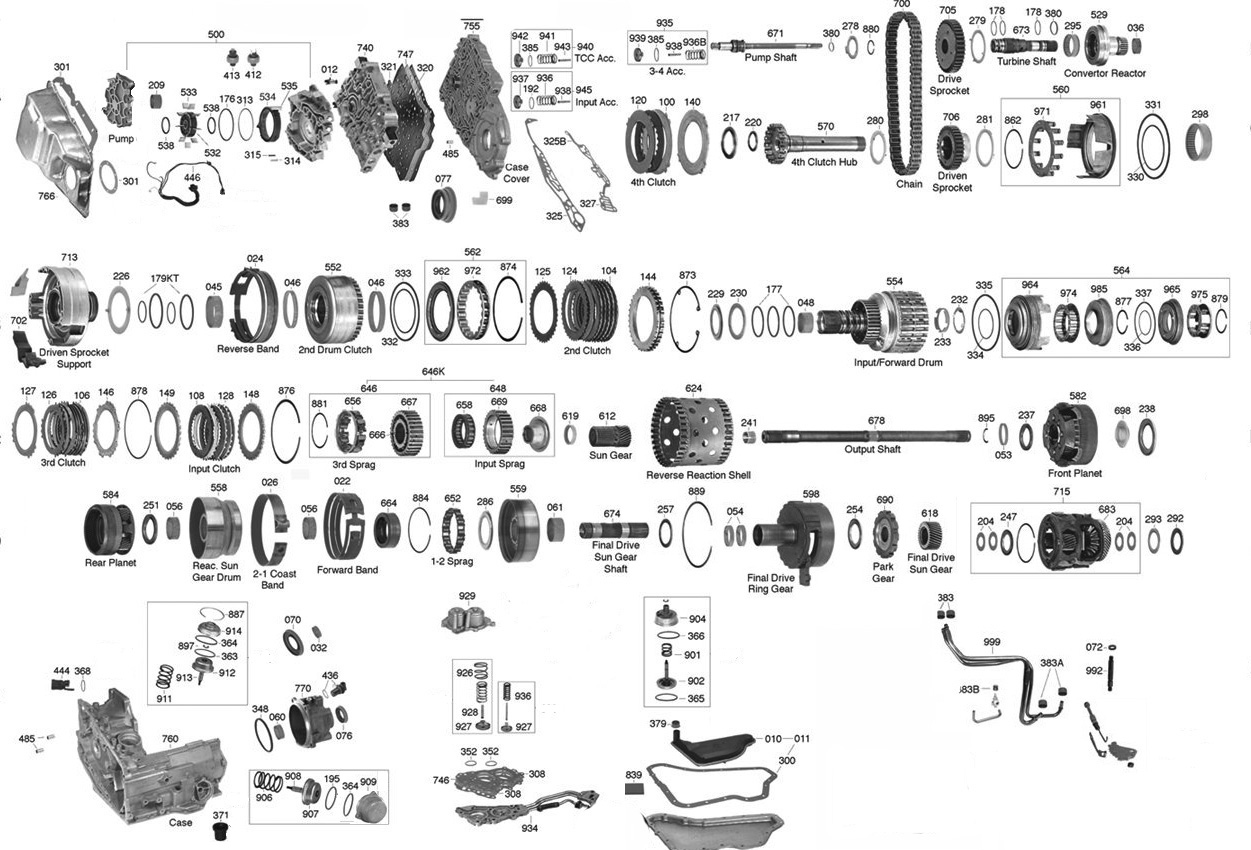

Shows how few FWD GM enthusiasts there are 'round these parts Kinda grimy when picked up: The -HD diffy parts were first to come out; the differential looks good and checks out as per planetary play spec in the FSM: Fluid out of the pan and TC was brownish-red and obviously overheated, but had no particles or specks in it. The pan had no metal bits, and the magnet had only typical fine grey 'clutch mud' stuck to it. Cracked open the filter with a hammer and chisel: Only some fine clutch mud, no metal particles. The third pic shows some black 'flakes' stuck between the felts.I know what that is already, but I'd be getting ahead of myself. Fri May 02, 2008 After Input and Reaction Carrier, Reaction Sun Gear, Manual 2-1 Band, 1-2 Support Drum and Forward Band removal: I inspected the Parking Link: And differential Ring Gear: Inside the case. They are fine, and I'm not going to bother removing them.

The case 95% cleaned: Pressure Test Plug and Vent check out OK, as do Forward and Reverse Servos and the Drive Sprocket Bearing: TC Stator Mount looks good: Another look at the Differential components now that they are all cleaned up: This metal clad axle seal needs replacing, and that comes in the Overhaul kit: Here's the roll pin that holds in the spider gear pinion: If that roll pin falls out, then this pinion: Is free to sling out of the diff carrier and bust your extension housing. Alternatively, sometimes the spider gears sieze to or wear down the pinion and the gears or pinion itself breaks. None of these things is good, all are caused or accelerated by rough treatment, and this is why we are all warned not to do one-wheel burnouts There are aftermarket limited slip differentials (LSD); but from what I've read the clutch-based ones do not have a good track record for longevity, and the true posi-lock GM Torsen diffy costs more than my car is worth. There are also aftermarket beefed-up output shafts, half axles, etc., but I'm not expecting to need any of that. Input Sun Gear, Input and Reaction Carrier: Input Sun Gear checks out OK. Input planetaries are well within play spec as per FSM.

One of the planetaries on the Reaction Carrier has slightly more play than the others, but is still within FSM spec. I'm calling it OK: If you've ever considered an -HD diffy upgrade, you may have been warned to be careful about a lube dam that the output shaft goes through. It sits between the Input and Reaction Carrier: This old plastic part was so brittle it literally started to crumble in my hand: Luckily, I can get a replacement for about $2 - Reaction Sun Gear and 1-2 Support Drum: The Support Drum has a one-way roller bearing inside: Both parts checked out OK, and the one-way bearing does its job. Manual 2-1 Band: The 2-1 manual band is marginal for reuse. For $10 I'll just get a new one. Forward Band: The forward band is burnt and must be replaced (About $50) - Bought this for the TC metal-clad oil seal. Mber=91352 POST Sat May 03, 2008 More parts inspection.

Reverse Drum: Part is OK. I picked up this tool to take apart the clutch assemblies: 2nd and Input / 3rd Clutch Assemblies: 2nd Clutches: These steels have some severe burned spots, and the frictions are pretty worn down. More evidence that the original owner of this tranny liked to punch it. The Master kit will have Borg Warner clutches and new steels. 2nd Clutch Spring and Piston: The piston has a rubber seal bonded to the bottom and must be replaced; that will come with the Master kit. Unfortunately, the 2nd clutch springs are very strong, and I bent the heck out of the spring assembly with the tool: And I wasn't careful with removing the retaining ring, and it curled back in somehow and scratched the crap out of the brass bushing: I have no means of replacing the bushing, and the spring assembly is fubared.

Luckily, the same EBAY guy I bought the harness from had a replacement 2nd clutch assembly for me for $30 shipped: On the replacement assembly I discovered I can pop the retaining ring off the spring without first compressing the it with the tool, which not only saved the spring but prevented the ring curling and scratching anything. I also discovered I can invert the the old 2nd clutch piston and use it to distribute the force of the tool to depress the new spring assembly without bending it, and have room to push the retaining ring back into place. Nice save Input / 3rd Clutch Assembly: 3rd Clutches: The 3rd clutches are different, in that they are steels on one side and frictions on the other (rather than separate steels / frictions). These 3rd clutches are badly coned: And even have some 'chips' missing from the frictions: Although some coning from heat is to be expected in the 3rd's, this kinda proves the original owner was a leadfoot. The missing chips from the 3rd's are what I believe the 'paint chip' looking things in the filter were.

The Master kit will have new Borg Warner 3rd clutches. Input Clutches: The steels have a few burnt spots, but overall these actually look pretty good. The Master kit will have new BW clutches and new steels. 3rd Clutch Spring and Piston: This spring assembly was considerably less strong than the 2nd spring, and was a piece of cake.

Like the 2nd piston, this one has a bonded seal and must be replaced (comes with the Master kit). Input Clutch Housing, Spring and Piston: This spring was weak and easy, too. The input piston is rather worn inside, where the input piston inner lip seal rides: And this (along with a crappily-designed OEM inner lip seal) is what leads to the infamous 'bang start' in these transmissions. NInfo.php The TransTec brand Overhaul kits include a re-designed 'long-lip' inner seal (along with some other fixes) designed to fix this: I also got a new input piston off EBAY for $10, and it is nice and smooth inside: Input / 3rd Sprag: This part checks out functionally in that the gears counter-rotate one direction and lock in the other. According to the book, the retaining ring on the top is not reuseable: And I don't know if the Master kit comes with this retainer. I ordered one from a local dealership for $6 just in case; when that comes in I'll be able to pop this open to inspect its innards.

Driven Sprocket Support, 4th Clutch Spring and Piston: This spring was really tame. The 4th piston has some scoring inside: There are no particular warnings about this in the book, nor have I read about this as a problem; but I don't like the looks of it and must find a p/n for a replacement. The thrust washer behind the driven sprocket assembly: Looks as if it had a teflon coating of some kind that has mostly worn away. I will be getting a thrust washer kit (about $15) that should replace this and many other thrust washers. Another look at the Drive and Driven Sprockets: The 37 / 33 originals at top, the 35 / 35 set I picked up at bottom. Even though I said I was planning to reuse the Drive Link: I'm having second thoughts about putting extra power to a 102k mile chain, and will likely order new ones for about $70.

Turbine Shaft looks fine and will be reused: A look at the 1-2, 2-3 and Manual 2-1 Accumulator parts: Everything in order there. For those considering a shift kit, that is basically some shims and some stronger replacement springs for the 1-2 and 2-3 accumulator pistons. All the brass bushings (except the one I messed up and subsequently replaced) look great. All the roller bearings, roller thrust bearings, and selective washers are fine.

I've now inspected everything I can (at least until the sprag retaining ring arrives). I've gone ahead and given this rebuild the green light, and ordered the Master kit (about $175); when that comes I can start reassembling stuff. For now, everything bagged, tagged, and boxed: Last edited by on Tue Jun 03, 2008 4:07 pm, edited 2 times in total. Mon May 05, 2008 Got the TC oil seal out with the Harbor Freight tool: Master Kit came in: Time to start putting some of this back together. Second Clutch Assemble: Parts laid out: New clutch frictions soak in ATF for 30 minutes: Moisten new 2nd piston lip with ATF: Piston was a bear to push into place.much tighter than the old one. Here the spring and clip are in place and ready for the tool: Invert the old piston and use as a 'washer' to avoid ruining this spring: Still leaves enough gap to push the snap ring into the groove: Done: Soaked clutches installed: New 2nd clutch pack all done: Driven Sprocket Support Components Assemble: After looking at it more closely, the scoring inside the 4th piston (see earlier post) was not in the location of the inner lip seal, but rather only where it travels at the top edge of the driven support.

So I decided to reuse the 4th clutch piston. New outer lip seal, moistened with ATF: Installing an ATF-soaked new inner seal using a specially homemade tool (aka, very small flatblade that I ground all sharp edges off of): It is crucial to get these lip seals seated properly, so that they sit in the groove with the lip sticking out all the way around.

It's also crucial not to nick or cut the seals; in some cases, I temporarily wrapped shafts in electrical tape while sliding on the seals to avoid running seals over grooves or sharp edges.this was in lieu of buying up all kinds of specialty Kent Moore J-tool seal protectors and slides. Also, you have to make sure that inner lips seat inside pistons properly and do not 'roll up' as you reinstall the pistons.another use for the rounded-off flatblade.

4th piston, spring and snap ring done: This is a '97 / early '98-style driven sprocket support that uses rubber 'quad rings' under the split-ring teflon oil seals; newer style (mid-'98 on) uses a different size teflon seal and does not use these quad rings. Tue May 13, 2008 Teflon Sealing Rings (Input / 3rd Clutch Hub and Input Shaft) I used a long, smooth, slow taper glass funnel (labware) to stretch the rings.

That seemed to work OK for getting them onto the shaft: I got these nylon clamps to resize the rings: That did not work out so well. When assembled to the driven sprocket support / 2nd clutch drum assemblies, they are not forming a positive seal (to air) for input and third clutch apply, even when the fluid channels in the support are filled with ATF.

I believe these clamps are making a depression or 'divot' (red arrow) and a 'hump' (green arrow) in the rings: I tried letting them sit a few days; then sit again overnight bathed in ATF; but they are just not reforming properly to make a seal. I thought about getting new sealing rings (or a kit) and trying again, maybe with strips of neoprene between the clamp and the ring; but these rings are not exactly cheap enough for such experimentation, and the proper j-tools are extremely uncheap. So I'm likely going to send the hub and the shaft in to Dave at tripleedgeperformance.com to install and size all 6 new rings for me.

Thu May 15, 2008 So the Trannyman's going to install all six new seals on the hub and shaft and size them for $20. Fri May 16, 2008 Moving on to Valve Body Reassembly: Removed the separator plate gaskets (wetting them thoroughly with ATF helped them come off relatively easily), then sprayed well with brake cleaner and hung to dry: There is an FSM test where you place the checkballs (10 in total) onto their little chamfered holes in the separator plate and see if light shines through from the bottom; all passed OK; will reuse with gaskets supplied in Master kit.

Had the test failed, GM now replaces the gasket / plate / gasket with a plate with gaskets pre-bonded to both sides.undoubtedly to ease assembly. For 97-03 the p/n is 24217552; for 04+ is 24224544. Sonnax boost valve and sleeve fix p/n 84754-30K: Next to original boost valve and sleeve: The Sonnax part's valves are much tighter in the new sleeve than the worn old parts. I think this will have been worth doing. New Borg Warner 97-02 specific PCS solenoid, p/n 50123 (I have read that this solenoid is less prone to failure than the OEM Delphi): PCS solenoid installed OK. Sonnax TCC relief valve fix p/n 84754-43K: Next to the original worn part: This valve has a scarf-cut teflon seal (and an extra in case you mess up) that requires sizing. Wed May 21, 2008 Parts from GMPD: 2 New Shift solenoids, about $15 each (p/n 24219819; not year-specific): New VB TCC apply valve end plug, about $5 (p/n 24208635): After these are installed, Valve Body assembly is ready for reinstall.

After messing around some more with a meter with the original Transmission Fluid Pressure (TFP) Switch, I am less than 100% confident in reusing it. The normally closed switches (of which the TC switch is one) are not responding as quickly as I'd like, even after more cleaning with contact cleaner. Maybe they are just too corroded. Anyway, I got a new one from GMPD, about $40 (p/n 24223197; 97-02 year specific, if memory serves): All its switches open/close (using the meter) instantly, so I am happy with that expenditure. Fri May 23, 2008 I decided it's not worth the labor of removing the Thrasher Shift Kit from my current trans versus buying a new shift kit. Got a TransGo SK-4T65E kit for about $50 shipped: Here are the springs and shims for the 1-2 and 2-3 accumulator (which I since installed): Plus the piston seals and new accumulator spacer plate from the TransTec Master kit: But it also came with firmer springs for the 3-4 accumulator in the case cover (which I went back and installed), which I have not seen in any other shift kit: The kit also came with other goodies. TransGo's version of a fix for the OEM short-lipped inner seal for the third clutch piston, a chamfered seal and a spring for the groove (not needed for me since the TransTec kit had a long-lipped seal): A new spring and boost valve (not needed for me since I got the Sonnax complete boost valve fix): A long-lipped seal for the reverse servo (but again TransTec kit already has this).

Wed May 28, 2008 Input/3rd Sprag installed into the clutches in the input/3rd clutch hub: The book says to line up all the little clutch teeth with a small screwdriver and simply slide the sprag in. I just gooped it up with goo (to make it stay in place during installation), then rotated and 'wiggled' it alot while the clutches lined up one-by-one and the sprag slowly fell into place.

You know it's all the way in when the sprag rests on the thrust bearing and is more or less flush with the top clutch plate. This took about an hour. Thu May 29, 2008 35-tooth Drive Sprocket (from a n/a GPGT trans) affixed to Turbine Shaft with snap ring: It was very delicate getting that snap ring back on over the green teflon rings without gouging the rings.

Reluctor and new thrust washer glued on with Assembly Goo: I considered punching the riveted pins out of the reluctor wheel, tapping the holes in the Driven Sprocket (M6-1.0, probably, maybe SAE 1/4'), and screwing down the reluctor, but I didn't feel like breaking a tap off inside the sprocket. Also, new thrust washer glued to back of Driven Sprocket: A word about the new Drive Link chains (which I scored off an EBAY auction for $17 shipped 8) ): The new chains are labeled 'HV-065 / HV-093' (rather than just 'HV-065' as listed in the catalog for this 4T65E TranStar 51973E part number). Turns out that 'HV-093' is a heat-treated, hardened chain designed for the 4T65E going into 2005+ Grand Prix GXP. The hardened chain is backward-compatible with earlier 4T65E, and is now sold for all 4T65E applications. The hardened chains are verified by the presence of two blue 'master' links, versus one blue link in the old chains.

New chains (in bag), versus old chains: That's pretty sweet Anyway, the chains on the sprockets: Then installed into the trans: Getting the turbine shaft into place took some Goo for lube and alot of wriggling and pushing. The new chains clear the case by 0.342' (versus about 1/4' with the old chains, which apparently were slightly stretched): New 4th Clutches and Steels: Note the copious fluid channels in these Borg Warner fibers; should reduce clutch burning in OD. Mon Jun 02, 2008 I probably paid a little more than I could have for some things, and definitely found bargains on others.

I was hoping to get this far for around $800 in parts, but I went slightly over. Man I have to tell you that is an awesome post you have for the rebuild of the 4T65E. It actually inspired me to do my own. The only thing that was wrong with mine is I lost 4th gear and decided to go on and rebuild it. Looked real good inside but I am replacing everything from seals to solenoids to steels. I've got a question for you concerning the pump. I had butterfingers and my vanes all fell out.

Inspection of the pump shows no grooves or abnormal wear, everything is nice and smooth. Would using the same pump and having the vanes not in the original location be a problem? Well I finished my 4T65E rebuild of my Pontiac and it shifts fine.

It's nice to have my 4th gear back also. This is what I replaced in mine. 1st & 2nd shift solenoid new thrust washer kit new oil pump shaft new sungear new front bands replaced all seals new steels new clutches new torque converter new chain new tranny oil filter new 4th clutch hub shaft Transgo shift kit new TCC Solenoid new pressure manifold switch new rear band new reverse band new check balls new pressure control solenoid (EPC) In all the parts ran about $600 thanks to new parts from Ebay.

Repair Manual Buick Lesabre

I was able to get the pressure manifold switch for $23.00 (new) when I have seen the prices double and triple that. Thanks for the advice and for putting up such an awesome post. » » » All times are UTC - 5 hours DST Related topics Topics Author Replies Views Last post 6 4158 Sat Mar 20, 2010 4:52 am 2 1733 Wed Jan 02, 2013 2:18 am 5 1738 Fri Nov 12, 2010 11:02 am 4 911 Tue Nov 24, 2015 12:42 pm 6 380 Wed Jan 17, 2018 12:15 am Who is online Users browsing this forum: No registered users and 4 guests You cannot post new topics in this forum You cannot reply to topics in this forum You cannot edit your posts in this forum You cannot delete your posts in this forum You cannot post attachments in this forum Search for: Jump to.